Title

Characterisation of emulsion formulations

Objective

To determine:

1. The effects of HLB surfactant on the stability of

the emulsion.

2. The effects of different oil phases used in the

formulation on the physical characteristics and stability of the emulsion.

Introduction

An emulsion is a thermodynamically unstable two-phase system consisting

of at least two immiscible liquids. It contains at least two immiscible liquid

where one of them is dispersed and dispersion medium. The dispersed liquid is known

as the internal or discontinuous phase, whereas the dispersion medium is known

as the external or continuous phase. In general, emulsion can be categorized

into 2 types, oil in water emulsion (o/w) and water-in-oil emulsion (w/o). . An

o/w emulsion is generally formed if the aqueous phase constitutes > 45% of

the total weight, and a hydrophilic emulsifier is used. Conversely, where water

or aqueous solutions are dispersed in an oleaginous medium, the system is known

as a water-in-oil (w/o) emulsion. W/O emulsions are generally formed if the

aqueous phase constitutes < 45% of the total weight and an lipophilic

emulsifier is used.

The HLB method (hydrophilic-lipophilic balance) is

used to determine the quantity and type of surfactant that is needed to prepare

a stable emulsion. Every surfactant is given a number in the HLB scale, that is

form 1 (lipophilic) to 20 (hydrophilic). Usually a combination of 2 emulsifying

agent is used to form a more stable emulsion. HLB value for a combination of

emulsifying agents can be determined by using the following formula.

The consistency of

emulsions varies from easily pourable liquids to semisolid creams. Thus, emulsions are used in many

routes of administration. Most commonly, emulsions are used for topical

administration. Emulsions are also used as an ointment bases and intravenously

administered as part of parenteral nutrition therapy.

Apparatus

and materials

a. Apparatus

8 test tubes, a 50ml measuring cylinder, 2 sets of

pasture pipettes and droppers, vortex mixer, weighing boat, 1 set of mortar and

pestle, light microscope, microscope slides, 1 set of 5ml pipette and bulb, 1

50ml beaker, a 15ml centrifugation tube, centrifugation apparatus, viscometer,

water bath (45 celsius) and refrigerator (4 celsius).

b. Materials

Palm oil, Arachis oil, Olive oil, Mineral oil,

Distilled water, Span 20, Tween 80, and Sudan III solution (0.5%)

Procedures:

1. Each test tube was labelled and marked 1 cm from

the base of the test tube.

2. 4ml of oil was mixed and 4ml of distilled water

into the test tube.

Group

|

Oil

|

1,5

|

Palm

oil

|

2,6

|

Arachis

oil

|

3,7

|

Olive

oil

|

4,8

|

Mineral

oil

|

3. Span 20 and Tween 80 were added into the mixture

of oil and water (refer Table 2). The test tube was closed and its content was

mixed with vortex mixer for 45 seconds. The time needed for the interface to

reach 1cm was recorded. The HLB value for each sample was recorded. Steps 1-3

were recorded in order to obtain an average HLB value of a duplicator.

Tube

no

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

Span

20

(drops)

|

15

|

12

|

12

|

6

|

6

|

3

|

0

|

0

|

Tween

80 (drops)

|

3

|

6

|

9

|

9

|

15

|

18

|

15

|

0

|

Table

2

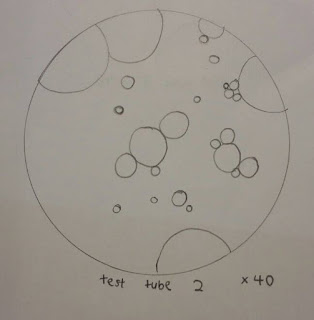

4. A few drops of Sudan III solution were added to

(1g) emulsion formed in a weighing boat and mixed homogenously. The spread of

the colour in the sample was compared. Some of the sample was spreaded on a

microscope slide and observed under light microscope. The appearance and

globule size formed was described and drawn.

5. Mineral Oil Emulsion (50 ml) was prepared from

the formulation below by using wet gum method according to Table 3a and 3b.

Mineral

Oil

|

(refer

Table 3b)

|

Acacia

|

6.25g

|

Syrup

|

5ml

|

Alcohol

|

3ml

|

Distilled

water qs

|

50ml

|

Table

3a

Emulsion

|

Group

|

Mineral

Oil (ml)

|

I

|

1,5

|

20

|

II

|

2,6

|

25

|

III

|

3,7

|

30

|

IV

|

4,8

|

35

|

Table

3b

6. 40g of emulsion was placed intoa 50ml beaker and

homogenized for 2 minutes using a vortex mixer.

7. 2g of emulsion (before and after homogenization)

was taken and placed into a weighing boat and labelled. A few drops of Sudan

III solution was added and mixed. The texture,

consistency, degree of oily appearance and the spreading of colour in the sample

under the light microscope was stated and compared.

8. The viscosity of the emulsion formed after

homogenization (15g in 50ml) was determined using viscometer that is calibrated

with “Spindle” type LV-4. The sample was exposed to 45 celsius (water bath) for

15 minutes and then to 4 celsius (refrigerator) for another 15 minutes. After

the exposure to the temperature cycle is finished and the emulsion had reached

room temperature (10-15 minutes), the viscosity of emulsion is determined. Step

8 was repeated again and an average value was obtained.

Readings

|

Viscosity(cP)

|

Average

|

|||||

1

|

2

|

3

|

4

|

5

|

6

|

||

Before

Temperature

Cycle

|

|||||||

After

Temperature Cycle

|

|||||||

Difference

(%)

|

|||||||

Table

4

9. 5g of homogenized emulsion was placed into a centrifugation

tube was placed and centrifuged (4500 rpm, 10 minutes, 25 celsius). The height

of the separation formed was measured and the ratio of the height separation

was determined.

Mineral

Oil (ml)

|

Ratio of separation

|

Average

|

Ratio

of separation phases

|

|||

20

|

||||||

25

|

||||||

30

|

||||||

35

|

||||||

Result

For

Palm Oil:

|

Palm oil

|

||||||||

|

Tube

number

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

Span

20 (drops)

|

15

|

12

|

12

|

6

|

6

|

3

|

0

|

0

|

|

Tween

80 (drops)

|

3

|

6

|

9

|

9

|

15

|

18

|

15

|

0

|

|

HLB

value

|

9.67

|

10.73

|

11.34

|

12.44

|

13.17

|

14.09

|

15.00

|

0.00

|

|

Time

of phase separation (min)

|

---

|

---

|

86

|

60

|

80

|

113

|

85

|

15

|

“---” = Time taken greater than 130

minutes (To find the average, 130

minutes used to represent the time taken for interphase to reach 1cm for “---”

For Olive Oil:

|

Olive oil

|

||||||||

|

Tube number

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

Span 20 (drops)

|

15

|

12

|

12

|

6

|

6

|

3

|

0

|

0

|

|

Tween 80 (drops)

|

3

|

6

|

9

|

9

|

15

|

18

|

15

|

0

|

|

HLB value

|

9.67

|

10.73

|

11.34

|

12.44

|

13.17

|

14.09

|

15.00

|

0.00

|

|

Time of phase separation (min)

|

---

|

---

|

57

|

11

|

32

|

14

|

37

|

0

|

“---” = Time taken greater than 130

minutes (To find the average, 130

minutes used to represent the time taken for interphase to reach 1cm for “---”

For Mineral Oil:

|

Mineral oil

|

||||||||

|

Tube number

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

Span 20 (drops)

|

15

|

12

|

12

|

6

|

6

|

3

|

0

|

0

|

|

Tween 80 (drops)

|

3

|

6

|

9

|

9

|

15

|

18

|

15

|

0

|

|

HLB value

|

9.67

|

10.73

|

11.34

|

12.44

|

13.17

|

14.09

|

15.00

|

0.00

|

|

Time of phase separation (min)

|

---

|

---

|

69

|

61

|

56

|

46

|

0

|

0

|

“---” = Time taken greater than 130 minutes (To find the average, 130 minutes

used to represent the time taken for

interphase to reach 1cm for “---”

For arachis oil (Group 2 B):

Group 2( Arachis

oil)

|

||||||||

Tube number

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

Span 20 (drops)

|

15

|

12

|

12

|

6

|

6

|

3

|

0

|

0

|

Tween 80 (drops)

|

3

|

6

|

9

|

9

|

15

|

18

|

15

|

0

|

HLB value

|

9.67

|

10.73

|

11.34

|

12.44

|

13.17

|

14.09

|

15.00

|

0.00

|

Time of phase separation (min)

|

---

|

79

|

75

|

35

|

27

|

40

|

20

|

0

|

HLB value =

|

[(quantity of surfactant 1)(HLB of surfactant 1) +

(quantity of surfactant 2)

(HLB of surfactant 2)]

|

quantity of

surfactant 1 + quantity of

surfactant 2

|

Calculation of HLB

values:

HLB value for Span 20

= 8.6

HLB value for Tween 80

= 15.0

Therefore, example of calculation:

HLB value for Tube 1 = (15 x 8.6) + (3 x 15.0)

(15 + 3)

=

9.67

HLB value for Tube 2 = (12 x 8.6) + (6 x 15.0)

(12 + 6)

=

10.73

HLB value for Tube 3 = (12 x 8.6) + (9 x 15.0)

(12 + 9)

= 11.34

HLB value for Tube 4 = (6 x 8.6) + (9 x 15.0)

(6 + 9)

=

12.44

HLB value for Tube 5 = (6 x 8.6) + (15 x 15.0)

(6 + 15)

=

13.17

HLB value for Tube 6 = (3 x 8.6) + (18 x 15.0)

(3 + 18)

=

14.09

HLB value for Tube 7 = (0 x 8.6) + (15 x 15.0)

(0 + 15)

=

15.00

HLB value for Tube 8 = (0 x 8.6) + (0 x 15.0)

(0 + 0)

=

0.00

For arachis oil:

Appearance and globule size under light microscope

Test tube

|

Shape

|

Globule size

|

Spread of colour

|

1

|

Round globule

|

Small

|

Not Even

|

2

|

Round globule

|

Big

|

Even

|

3

|

Round globule

|

Tiny

|

Even

|

4

|

Round globule

|

Small

|

Not Even

|

5

|

Round globule

|

Tiny

|

Even

|

6

|

Round globule

|

Small

|

Even

|

7

|

Round globule

|

Tiny

|

Not Even

|

8

|

Round globule

|

Tiny

|

Not Even

|

2g of emulsion before and after homogenization

For

20ml mineral oil

|

Before

homogenization

|

After

homogenization

|

Texture

|

Non

homogenous (spacious)

|

Homogenous

(packed)

|

Consistency

|

Less

consistent-crystal clump together

|

More

consistent-crystals dispersed

|

Degree

oily appearance

|

More

greasy

|

Less

greasy

|

Spreading

of colour

|

Less spreading

|

More

spreading

|

For

25 ml mineral oil

|

Before

homogenization

|

After

homogenization

|

Texture

|

Non

homogenous

|

Clear

and homogenous

|

Consistency

|

Less

consistent

|

More

consistent

|

Degree

oily appearance

|

More

greasy

|

Less

greasy

|

Spreading

of colour

|

Less

even distribution

|

Better

even distribution

|

For

30ml mineral oil

|

Before

homogenization

|

After

homogenization

|

Texture

|

Course

and not homogenous

|

Smooth

and homogenous

|

Consistency

|

Not

consistent,less viscous

|

Consistent

|

Degree

oily appearance

|

More

greasy,spherical globules

|

Les

greasy and aspherical globules

|

Spreading

of colour

|

Unevenly

spreading

|

Evenly

spreading

|

For

35ml mineral oil

|

Before

homogenization

|

After

homogenization

|

Texture

|

More

watery and non viscous

|

Less

watery and more viscous

|

Consistency

|

Not

consistent and non viscous

|

Consistent

and mor viscous

|

Degree

oily appearance

|

More

greasy and more globules

|

Less

greasy and globules

|

Spreading

of colour

|

Unevenly

distribution

|

Evenly

distribution

|

For Viscosity Of Emulsion:

20 ml of mineral oil

Readings

|

Viscosity

(cP)

|

Average

|

|||||

1

|

2

|

3

|

4

|

5

|

6

|

||

Before Temperature Cycle

|

42

|

42

|

36

|

24

|

30

|

24

|

33

|

After Temperature Cycle

|

48

|

45

|

40

|

30

|

38

|

36

|

39.5

|

Difference(%)

|

19.7

|

||||||

25ml of mineral oil

Readings

|

Viscosity

(cP)

|

Average

|

|||||

1

|

2

|

3

|

4

|

5

|

6

|

||

Before Temperature Cycle

|

30

|

30

|

30

|

30

|

30

|

30

|

30

|

After Temperature Cycle

|

44

|

46

|

46

|

48

|

45

|

46

|

45.8

|

Difference(%)

|

52.7

|

||||||

30ml of mineral oil

Readings

|

Viscosity

(cP)

|

Average

|

|||||

1

|

2

|

3

|

4

|

5

|

6

|

||

Before Temperature Cycle

|

60

|

48

|

54

|

48

|

48

|

54

|

52

|

After Temperature Cycle

|

83

|

70.4

|

80.1

|

72.4

|

70.4

|

80.1

|

76.1

|

Difference(%)

|

46.3

|

||||||

35ml of mineral oil

Readings

|

Viscosity

(cP)

|

Average

|

|||||

1

|

2

|

3

|

4

|

5

|

6

|

||

Before Temperature Cycle

|

3.6

|

3.9

|

6.9

|

3.9

|

18.3

|

17.1

|

9.0

|

After Temperature Cycle

|

14.4

|

19.2

|

10.8

|

8.4

|

7.2

|

8.4

|

11.4

|

Difference(%)

|

26.7

| ||||||

Mineral Oil

(ml)

|

Ratio of

separation phase

|

Average

|

Ratio of

separation phase

|

||

20

|

4.00

|

3.50

|

4.00

|

3.83

|

0.77

|

25

|

3.00

|

3.30

|

3.50

|

3.27

|

0.66

|

30

|

2.86

|

2.70

|

2.86

|

2.81

|

0.56

|

35

|

2.25

|

2.25

|

2.15

|

2.22

|

0.44

|

Stable emulsion means longer time for phase separation to

occur. For palm oil, the HLB value

that brings to stable emulsion is 11.34. This means that the stable emulsion of

palm oil can be prepared by adding 12 drops of Span 20 and 9 drops of Tween 80.

For arachis oil, the HLB value that

can give stable emulsion is 11.34. For olive

oil, the HLB value that can give stable emulsion is 11.34. For mineral oil, the HLB value that can

give stable emulsion is 10.70. These show that different oils with different

HLB values require different combination of surfactants in order to produce a stable

emulsion.

From

the experiment for arachis oil which is done by our group, it was found that

emulsion from test tube 1, 2 and 3 where the HLB values are 9.67, 10.73 and

11.34 respectively give the most stable emulsions. Their phase separation time

is very long if compared to the other test tubes. Thus, the corresponding HLB

value of 9-13 gives the most effective surfactant for the oils used in this

experiment. Appropriate HLB value is important in determining the stability of

the emulsion. Meanwhile, emulsions from tube 7 and 8 give the lowest stability

where the phase separation time is the shortest. This is because the absence of

surfactant as an emulsifying agent in tube 7 and 8. Surfactant enhances the

distribution of oily phase into the aqueous phase (o/w emulsion) or the

distribution of aqueous phase into the oily phase (w/o emulsion).

A

low HLB value have more hydrophobic group while the high HLB value have more

hydrophilic group. Span is hydrophobic and is used to make w/o emulsion.

Meanwhile, tween is hydrophilic and is used to form o/w emulsion. In the

stabilization of oil globules, it is essential that there is a degree of

hydrophilicity to confer an enthalpic stabilizing force and a degree of

hydrophobicity to secure adsorption at the interface. So, a combination of both

offers a suitable HLB value which matches with the system and produces a stable

emulsion. The HLB value of the surfactant that fulfills the required HLB value

of the emulsion will form the stable emulsion and vice versa. The emulsion is

formed by reducing the surface tension of the two immiscible liquid through the

presence of surfactant at the interface. Generally, a combination of surfactant

is better than a single surfactant, which produces more stable emulsion.

During

this experiment , we did mixing the emulsion homogenously.Before

homogenization, the globules are not in uniform size and are coarse. There has

a combination of small, intermediate and large size globules. However, the size

of globules becomes uniform after homogenization and all globules are in

smaller size. About the greasiness, the emulsion is greasy and less viscous

before homogenization due to the reason of unemulsified oil. However, the

emulsion becomes smoother and more viscous after homogenization. This is

because the sample tube is spun in the high rate and breaks the globules into

smaller sizes. Besides that, the emulsion is less consistent before

homogenization. However, the consistency of the emulsion is increased and the

degree of oily are decreased after homogenization because during

homogenization, forces are applied to the emulsion and thus it causes a better

emulsifying effect to take place. After adding Sudan test III solution, the

colour of the emulsions becomes milky. It shows good colour dispersion in the

emulsions.

Sudan

test is a group of azo compound used as biological stains for fat. It is used

to show the shape and physical characteristic of oily emulsion. It can

differentiate which emulsion is oil-in-water emulsion or water-in-oil emulsion

by determining the amount of globules in red colour and the colourless

globules. Sudan solution is a red colour solution. It is dissolved in oily

phase of the emulsion. So, it will cause the oily globules stain in red colour.

The colour dispersion of the emulsions before homogenization is not consistent.

However after the homogenization, the colour of dispersion is more consistent.

Thus, the emulsion formed is considered as o/w emulsion.

For viscosity of emulsion after

homogenization

Graph 1.

Based on the graph 1, the percentage difference of viscosity (%) increases as the amount of mineral oil used increases. But percentage difference of viscosity (%) started to decrease when using 30 and 35 ml of mineral oil. All type of emulsion is exposed to the same temperature and they have the same volume, but different proportion of emulsifying agent, oil and water proportions. The percentage difference is the difference between the viscosity before and after the temperature cycle. For 20 mL of mineral oil, the percentage difference of viscosity is small which is 19.70% because the emulsion is not too viscous. For 25 mL of mineral oil, the percentage difference of viscosity is 52.67% which is much higher than mineral oil of 20 mL and that is because the emulsion is getting more viscous when adding more mineral oil into it. For 30 and 35 mL of mineral oil used, the percentage difference is 46.30% and 26.70% which is lower than 25 mL of mineral oil used. So this might be due to some errors occurs during handling the experiment because the percentage difference should be higher than 25 mL of mineral oil used. The percentage difference of viscosity (%) should increase with increasing amount of mineral oil used.

Viscosity

means a quantity expressing the magnitude of internal friction , as measured by

the force per unit area resisting a flow in which parallel layers unit distance

apart have unit speed relative to one another . In simple term , it can be

explain as a measurement of a fluid’s internal resistance to flow.

Besides,

in this experiment, the other objective is to test the physical effects and

stability on the emulsion formulation due to different amount of emulsifying

agent. Thus it will be tested at different temperature , and can also effect the

emulsifying agent. Emulsifying agent will prevent coalescence of droplets and

maintain the individual droplets in the continuous phase. It also acts by

adsorb onto the oil-in-water interface and lower the surface interfacial

tension. In addition, emulsifying agent tends to promote dispersion of the

phase in which they do not dissolve very well.

Increase

in amount of mineral oil used in an emulsion will increase amount of acacia

that will be use as an emulsifying agent . This is due to the ratio 4:2:1. The

4 part represent oil part , 2 part for the water while 1 part is for the

emulsifying agent.

Since

acacia does not dissolves in oil, so this will form oil-in-water emulsion. Increase

in temperature will also increase droplet size and reduce viscosity. The

increasing of droplet size will make the emulsion difficult to disperse and

easily separate to two layers . While in cold temperature , the emulsion will

become thicker and viscous and difficult to be separate in two layer.

The

value of emulsion after the temperature cycle is in greater value than before

the temperature cycle. This happen due to loss of some proportion of the volume

during heating process. During heating process the molecule will vibrate but

interact less. Thus the viscosity value is low.

For the ratio of separation phase

Centrifugation

of emulsion is used to separate the oil phase from the aqueous phase. From the

result obtained , it proved that the phase of separation ratio will be lower if

the more volume of mineral used in the formulation. Oil is less dense than

water thus it will be form at top layer after the centrifugation.

If

the oil phase is at high level , thus the separation phase will be shorter and

result in lower phase separation value.

Throughout

this experiment , there were some errors that occur. So , there are some

precaution step that we need to take as example we must make sure that the room

temperature of the laboratory is constant as it will affect the changing

properties of surfactants. Besides , we need to be aware of the parallax error

that might occur .

Since

the experiment of different volume of mineral use were done by different group

in the laboratory thus the result obtained might differ a bit than the

theoretical result.

Conclusion

1) Combination

of surfactants form a more stable emulsion than a single surfactant. Different

oily phase need a different value of HLB surfactant so that the most stable

emulsion can be formed.

2) Homogenization process

is applied in this mineral oil emulsion to reduce the size of droplets in

liquid-liquid dispersions. Before homogenization, the texture of emulsion is

non-homogenous, less consistency, more greasy in degree of oily

appearance and less spreading of colour. After homogenization, the texture of

emulsion is homogenous, more consistent, non greasy in degree of oily

appearance and more evenly spreading.

3) In oil-in-water emulsion, decrease in

temperature may cause high viscosity of an emulsion and vice versa. High

viscosity will increase the time for the separation of emulsion into two

layers.

4) As more volume of mineral oil is used in

formulation, a shorter separation phase will exhibit and this indicates a lower

phase separation value.

5) The higher the amount of mineral oil used,

the higher the amount of emulsifying agent (acacia) needed to lower the surface

interfacial tension.

6) The emulsion stability increases as the HLB

value increase because the droplet size decreases.

jReferences

1. http://chemistscorner.com/hlb-the-easiest-way-to-create-an-emulsion/

2. http://journal.scconline.org/pdf/cc1968/cc019n10/p00683-p00697.pdf

3. http://www.particlesciences.com/news/technical-briefs/2011/emulsion-stability-and-testing.html

4. Florence A.T. 1998.

Physicochemical Principle of Pharmacy, 3rd Edition

5. Aulton, M.E.

Pharmaceutics: The science of dosage form design. Edinburgh: Churchill

Livingstone.

6. http://medical-dictionary.thefreedictionary.com/Sudan+stain+test

No comments:

Post a Comment